Specifications of INA Bearing SCE47-S106UH-L140/80

Main Dimensions & Performance Data

| Cr | 4100 N | Basic dynamic load rating, radial |

| C0r | 3900 N | Basic static load rating, radial |

| nG | 35000 1/min | Limiting speed |

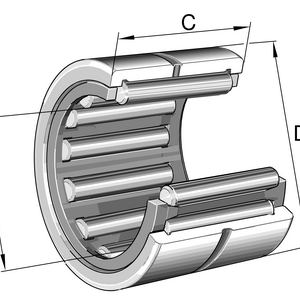

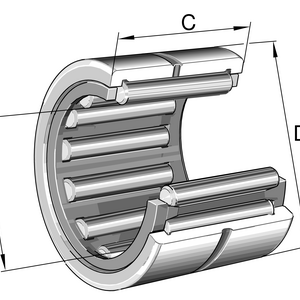

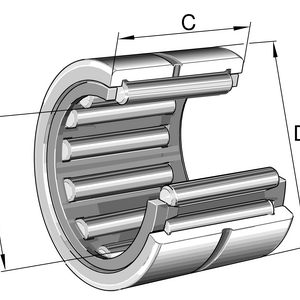

| D | 11.112 mm | Outside diameter |

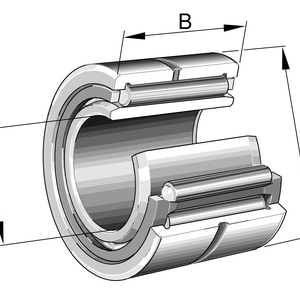

| Fw | 6.35 mm | Under roller diameter |

| C | 11.112 mm | Width |

Dimensions

Additional information

Temperature range

| Tmax | 140 u00b0C | Operating temperature max. |

| Tmin | -30 u00b0C | Operating temperature min. |