Specifications of FAG Bearing 22320-E1-XL-K-T41A

Additional information

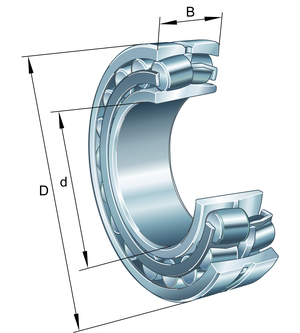

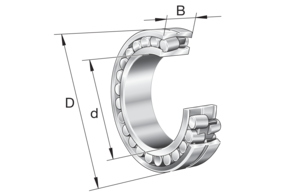

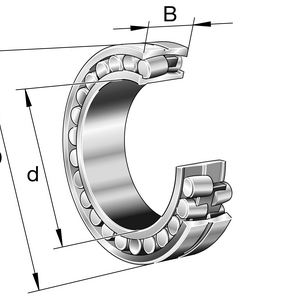

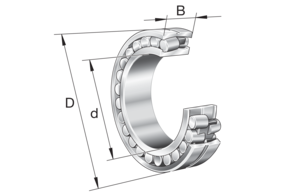

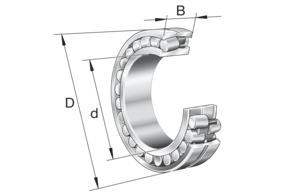

Main Dimensions & Performance Data

| Cr | 810000 N | Basic dynamic load rating, radial |

| C0r | 920000 N | Basic static load rating, radial |

| d | 100 mm | Bore diameter |

| Cur | 77000 N | Fatigue load limit, radial |

| nG | 3300 1/min | Limiting speed |

| D | 215 mm | Outside diameter |

| nδr | 2380 1/min | Reference speed |

| B | 73 mm | Width |

Dimensions

| D1 | 184.7 mm | Bore diameter outer ring |

| ds | 6.3 mm | Diameter lubrication hole |

| rmin | 3 mm | Minimum chamfer dimension |

| d2 | 130.2 mm | Raceway diameter of the inner ring |

| ns | 12.2 mm | Width of lubricating groove |

Calculation factors

| Y1 | 2.03 | Dynamic axial load factor |

| Y2 | 3.02 | Dynamic axial load factor |

| e | 0.33 | Limiting value of Fa/Fr for the applicability of diff. Values of factors X and Y |

| Y0 | 1.98 | Static axial load factor |

Mounting dimensions

| Da max | 201 mm | Maximum diameter of housing shoulder |

| da max | 129 mm | Maximum diameter of shaft shoulder |

| ra max | 2.5 mm | Maximum recess radius |

| db min | 110 mm | Minimum cavity diameter of the sleeve |

| Ba min | 7 mm | Minimum cavity width of the sleeve |

| da min | 114 mm | Minimum diameter shaft shoulder |

Temperature range

| Tmax | 200 ℃ | Operating temperature max. |

| Tmin | -30 ℃ | Operating temperature min. |