Specifications of TIMKEN Bearing 22308EMW33W800C4

Specifications

| Design Unit |

Metric |

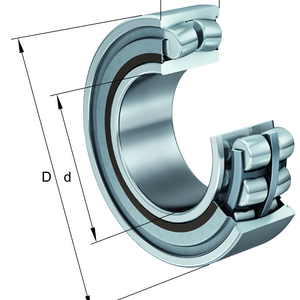

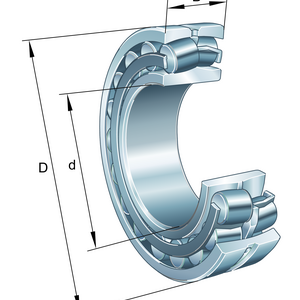

| d – Bore |

40 mm |

| Bearing Weight |

1.1 Kg2.3 lb |

| Cage Type |

EM |

| Cage Material |

Brass |

| Superseded Part |

22308YMW33W800C4 |

Dimensions

| D – Outer Diameter |

89.993 mm3.543 in |

| B” – Inner Ring Width |

33 mm1.2992 in |

| B – Outer Ring Width |

33 mm1.2992 in |

Abutment and Fillet Dimensions

| R – Inner Ring “To Clear” Radius1 |

1.5 mm0.060 in |

| r – Outer Ring “To Clear” Radius2 |

1.5 mm0.06 in |

| da – Inner Ring Backing Diameter |

53.000 mm2.100 in |

| Da – Outer Ring Backing Diameter |

81.00 mm3.200 in |